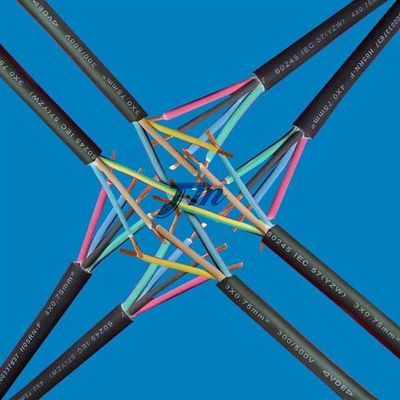

General Rubber sheathed cable It uses five types of copper conductors as the conductive core. During the production process, it is often found that copper conductors are oxidized and discolored, which seriously affects the quality of products and has become a long-standing technical problem for many cable manufacturers in China. Copper is a transition metal, which is easily oxidized to black CuO by oxygen in the air under acidic conditions. When there is water film or water droplet on the surface of copper conductor, because there is a lot of dust in the atmosphere, such as smoke, coal, automobile exhaust, chloride and other acid, alkali, salt particle dust, etc., these harmful substances can form electrolyte when dissolved in the water film or water droplet, thus intensifying the oxidation discoloration of copper conductor. The light ones affect the appearance quality and product quality of products, while the heavy ones affect the use of copper conductors, resulting in waste of production costs. Therefore, copper conductors must be kept properly, and attention shall be paid to prevent oxidation and discoloration.

In principle, the metallic copper used for cables mainly includes physical methods to block the contact between copper and humid air, cathodic protection redox method to prevent the oxidation of copper conductor, chemical methods to generate passive film on the surface of copper conductor to prevent oxidation, or spraying special liquid on the surface of conductor for protection. Take the production of general rubber sheathed cable as an example, the main method of anti oxidation control in each process.

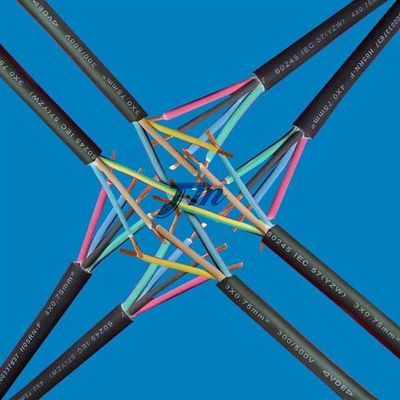

one Transportation, testing and storage of copper rods before entering the factory: Most cable enterprises in China use copper as outsourcing, so high-quality metal copper rods should be selected to standardize the supplier's transportation, delivery process and system. The incoming inspection of copper rods should be carried out in accordance with GB/T 3048.2 or the enterprise standard of cable enterprises. The storage of copper rods can be covered with plastic cloth or plastic film, that is, the simplest physical barrier method to prevent the contact between copper rods and humid air. When receiving copper rods, the workshop must visually inspect the copper rod coils one by one to see if there is any blackening, and control it from the source of production.

two . Control of copper rod drawing process: the drawing of 0.4mm single wire generally adopts continuous annealing copper large drawing machine and medium drawing machine, which need to go through the processes of paying off, drawing and annealing, cooling, drying, take-up, etc. First of all, the appropriate mold should be selected, and it must not be too small, or it will force the lattice of copper to change, which will aggravate the sharp rise of metal temperature. Secondly, before starting the machine, check the acidity and alkalinity of the emulsion to ensure that it is an alkaline solution. At the same time, antioxidant should be added to the drawing oil to form a passive film on the surface of the copper conductor to prevent oxidation; During paying off, keep the paying off tension stable and even without excessive vibration; During wire drawing, the operator shall ensure proper water level to ensure uniform annealing degree and avoid insufficient or excessive annealing; During take-up, there should be no residual liquid on the surface of the copper conductor. A piece of dry felt (often replaced) can be placed in front of the take-up to ensure the drying of the monofilament. Finally, seal the lower wall of the wire drawing with transparent plastic film, store it in a dry environment, and wait for circulation. Otherwise, there will be a risk of oxidation with humid air due to the high temperature of the conductor surface.

three Copper wire stranding (bundle stranding) and insulation rubber, sheath rubber extrusion process: take copper wire stranding as an example. During the stranding process, the metal copper lattice changes structure through various pressing dies. Under the effect of strong external force, the temperature of copper conductor after overmolding is significantly higher than that before overmolding, so the outer layer of copper conductor is easy to oxidize. Therefore, the antioxidant (0.3% benzotriazole alcohol solution) can be dropped into the copper wire with the infusion hose in the process of stranding. The dropping standard should be based on the fact that it just soaks into the surface of the copper wire, so as to avoid too little local oxidation or too much waste. After all the anti oxidation work is ready and stable, start the machine again. The take-up reel shall be dry at the take-up reel. After the take-up reel is full, it shall be sealed with transparent plastic film. The conductor shall be longitudinally wrapped or wrapped with polyester tape before extrusion insulation, and the substance in rubber insulation material shall be placed to corrode the conductor. During the extrusion process of insulating rubber and sheath rubber, water shall be prevented from entering the wire ends, which may lead to oxidation and blackening of the wire ends. The above methods can effectively prevent the oxidation of conductors of general rubber sheathed cables.