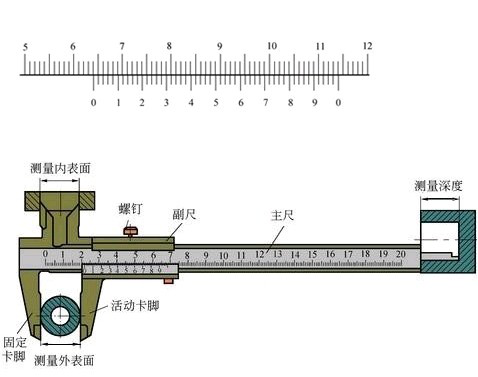

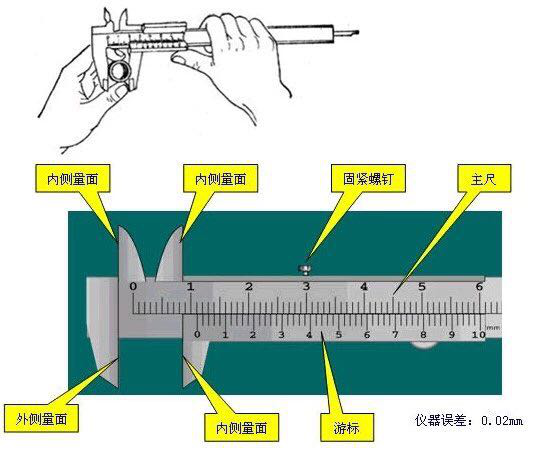

New energy cable manufacturer Vernier caliper is an instrument commonly used in industry to measure length. It can be directly used to measure workpieces with high accuracy, such as the length, inner diameter, outer diameter and depth of some cable wires. In daily work, many people will use it. Almost all friends are familiar with it. The vernier caliper seems simple, but do you really use it correctly? As a widely used high-precision measuring tool, vernier caliper is composed of a main ruler and a sliding vernier attached to the main ruler. If divided according to the scale value of the vernier, the vernier caliper can be divided into three types: 0.1, 0.05 and 0.02mm.

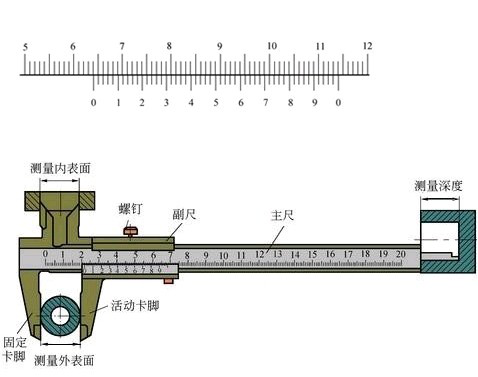

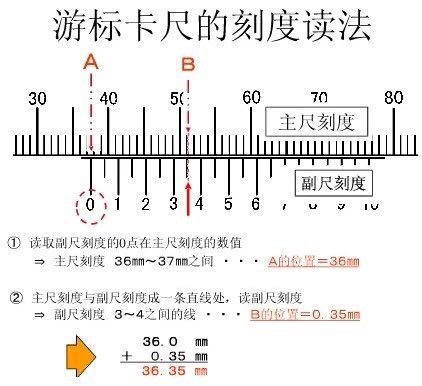

Reading method of vernier caliper

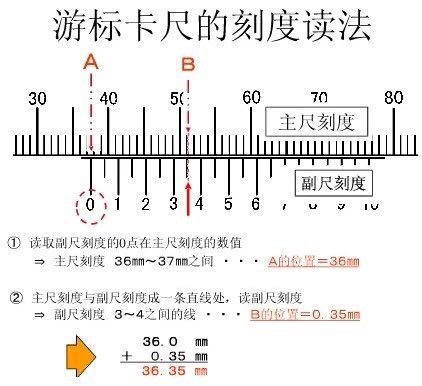

Taking the precision vernier caliper with a scale value of 0.02mm as an example, the reading method can be divided into three steps:

1) Read the whole millimeter according to the latest scale on the main ruler to the left of the auxiliary ruler zero line;

2) Read the decimal by multiplying the number of scribes aligned with the scale on the main ruler by 0.02 on the right of the secondary ruler zero line;

3) The total dimension is the sum of the integer and decimal parts above.

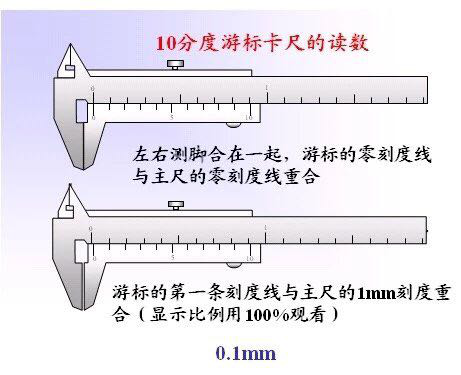

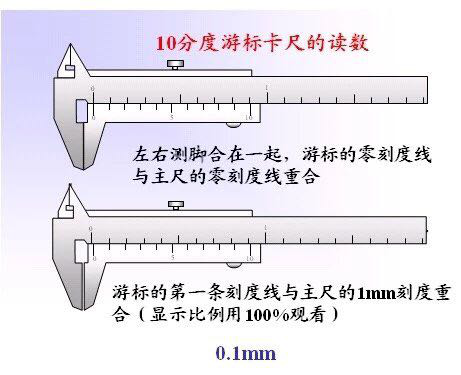

Principle and Reading of Vernier Caliper Micrometer .ppt The minimum graduation of the main ruler is 1mm , on vernier ten A small scale whose total length is equal to 9mm Therefore, each graduation of the vernier is different from the minimum graduation of the main ruler 0.1mm When the left and right measuring feet are combined, the zero scale line of the vernier coincides with the zero scale line of the main ruler

0.02mm Reading method of vernier caliper

As shown in the figure above, auxiliary ruler zero Scale in front of the main ruler pointed by the line 64mm , auxiliary ruler zero No. after the line nine The line is aligned with a scribed line of the main ruler. Auxiliary ruler zero No. after the line nine Bars represent:

0.02x9= 0.18mm , so the size of the measured workpiece is 64+0.18=64.18mm

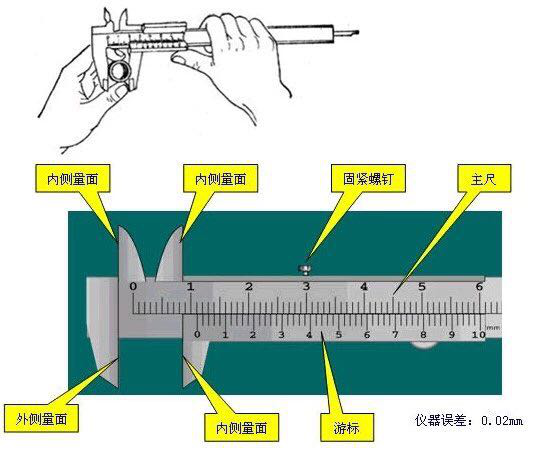

Usage of vernier caliper

Close the measuring jaws together and check whether the zero scale line of the vernier and the main ruler is aligned. If it is aligned, it can be measured: if it is not aligned, zero error shall be recorded: the zero scale line of the vernier on the right side of the zero scale line of the ruler body is called positive zero error, and the left side of the zero scale line of the ruler body is called negative zero error (this specification method is consistent with the provisions of the number axis, where the origin is positive on the right and negative on the left).

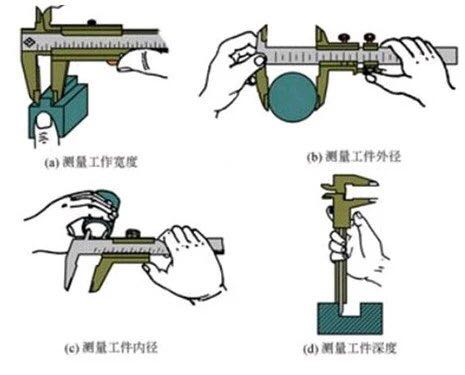

During measurement, the right hand holds the ruler body, the thumb moves the vernier, and the left hand holds the object to be measured for the outer diameter (or inner diameter), so that the object to be measured is located between the external measuring jaws. When it is tightly attached to the measuring jaws, the reading can be taken, as shown in the following figure:

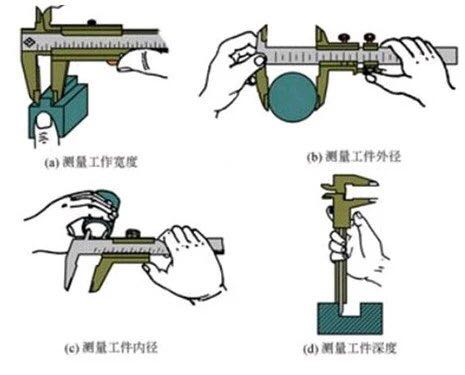

Application of Vernier Caliper

As a common measuring tool, the vernier caliper can be specifically used in the following four aspects:

1) Measure the width of the workpiece

2) Measure the outer diameter of the workpiece

3) Measure the inner diameter of workpiece

4) Measure the depth of workpiece

The specific measurement methods of these four aspects are shown in the following figure: