May 25, 2022 New energy cable -Importance of abrasion resistance of cables

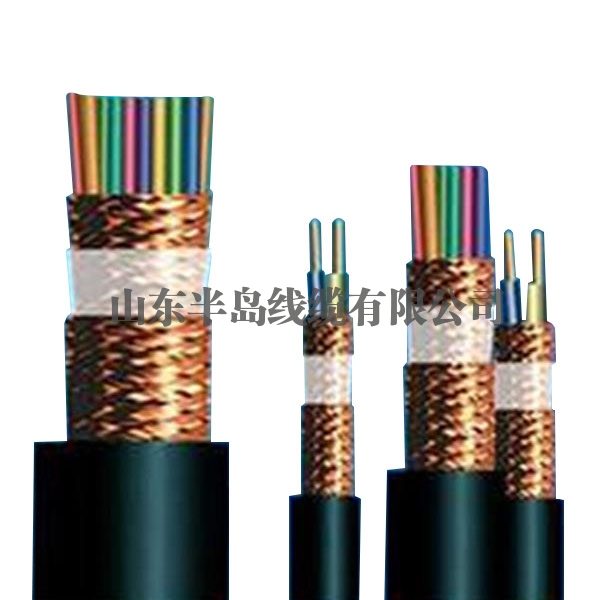

The main abrasion resistant coating of abrasion resistant cable is composed of PVC, polyurethane, and 3 composite PETP. Its application scope in the industry is mainly due to the relatively harsh, dusty and oily environment in most parts of the industry. Therefore, wear-resistant cable is used as the main cable in these fields.

Some people may wonder why wear-resistant cables cannot be used if this place is dusty and still an oil exploration area. Here, I want to remind you that although this kind of cable is called wear-resistant cable, it does not mean that it should be used everywhere. Sometimes it cannot be used in places with much oil and dust. In addition to the abrasion resistance of the abrasion resistant cable, it also has other characteristics, such as ultraviolet resistance.

Wear resistant cable has a wide range of applications, also because it can be used in some very harsh environments. The main function of wear-resistant cable is to prevent the damage caused by dragging the wire, and also protect the wire to a certain extent. Therefore, the wear-resistant property of the cable is extremely necessary. Because wear-resistant cables can be widely used in many places, especially in the industrial field, there will be a higher frequency of use. The wide application of wear-resistant cable has also brought a certain market. No matter in what field, its use frequency is gradually increasing, so wear-resistant cable is also widely favored by people.

Cables have been widely used in our daily life. Whether in families or in some factories, we need to use cables to provide power to support our daily work and life. But for the cables we need to use, in some places, it is not so simple, not just like the family environment, but also has a variety of harsh environments. For example, in oil areas, cables also need to be used, and in this case, wear-resistant cables need to be used.