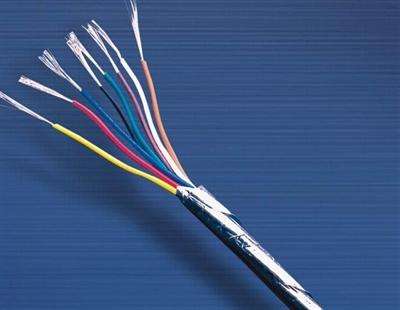

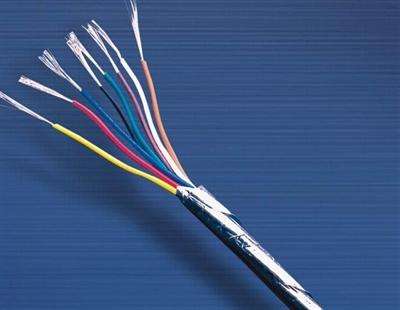

Computer cable belong to Cables for electrical equipment This cable is applicable to electronic computers and automatic instruments with rated voltage of 500V and below, which have high requirements for anti-interference. According to the use requirements of different environments and equipment, the cable insulation can be made of polyethylene, polyvinyl chloride, cross-linked polyethylene, fluoroplastic, silicone rubber and other materials.

The minimum ambient temperature for conventional computer cable laying is 0 ℃.

Maximum allowable working temperature of cable for a long time:

Insulation material name

Maximum allowable operating temperature (℃)

PVC 70

Polyethylene 70

Cross linked polyethylene 90

Polyolefin material 90, 105, 125, 150

Silicone rubber 180

Fluoroplastics 200

Minimum bending radius: the non armored structure shall not be less than 6 times the outer diameter of the cable, and the armored or copper tape shielded structure shall not be less than 12 times the outer diameter of the cable.

The insulation resistance shall meet the following requirements after 1 min of stable charging with DC 500V voltage test at 20 ℃:

Minimum insulation resistance of insulating material M Ω· km

Polyethylene, cross-linked polyethylene, fluoroplastics 3000

PVC, silicone rubber 25

There shall be no open circuit between the twisted pair shields and between the twisted pair shield and the general shield

The cable core and the core, as well as the core and shield or other metal layers shall withstand 50Hz, AC voltage 2000V/1min or 1500V/5min without breakdown.

Polyethylene has high insulation resistance, good voltage resistance, small dielectric coefficient, small influence of dielectric loss temperature and frequency change, which can not only meet the requirements of transmission performance, but also ensure the service life of the cable.

In order to reduce mutual crosstalk and external interference between circuits, the cable shall be shielded. Shielding materials include tinned or non tinned copper wire, copper tape, copper plastic composite tape, aluminum plastic composite tape, etc. The metal tape is produced by winding, and the coverage rate is usually not less than 15%, but there are special provisions in specific standards, such as TICW/06, which stipulates that the coverage rate of shielding metal tape should not be less than 25%; The metal wire shall be produced by braiding, and the braiding coverage rate shall not be less than 80%. If there are high requirements for anti-interference, the coverage rate may not be less than 90%.

The shielding requirements of cables are based on different occasions: sub shielding (only for twisted pair groups, each twisted pair group has shielding), general shielding (only after the cable core is cabled, there is a layer of general shielding), sub shielding+general shielding (including the above two structures at the same time). According to the higher requirements of users and use occasions, the overall shielding structure can adopt the composite shielding mode, that is, it contains two layers of shielding, which is composed of metal tape wrapping+metal wire braiding.

Note: If the cable has a sub shielding structure, the shielding pairs should have good insulation performance. Polyester tape or other non hygroscopic tape should be wrapped outside the sub shielding.

The above are the relevant technical parameters of the computer cable, please call the company for consultation.