Chapter I General

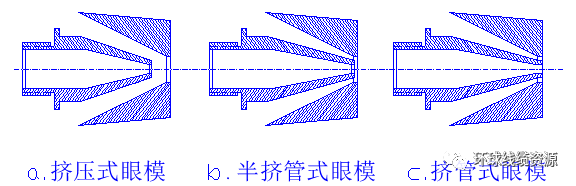

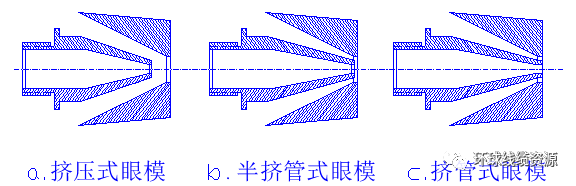

The eye mold for extrusion is an important part of the final finalization of wires and cables. The quality of wire and cable products - shape, appearance, etc. - will be directly affected by the mold design. The classification of extrusion molds can be directly divided into three types: There are three types of extrusion type, semi tube type and extrusion type. The specific form of the mold is as follows:

1. Extrusion die:

The internal mold of the extrusion mold has no tubular bearing diameter part, and the internal mold is shrunk behind the outer mold gallery. The molten material is finally shaped through the external mold by pressure, and the extruded plastic layer is compact in structure and flat in appearance. The angle between the internal mold and the external mold determines the material flow pressure. The size and surface finish of the internal mold and the external mold directly affect the surface quality and shape of the wire. The glue output of extrusion extrusion is relatively low. Its disadvantages are: Eccentricity is difficult to adjust, and the thickness of insulation layer is difficult to control. Moreover, when the core wire is bent, it is easy to cause the eccentricity of the plastic layer, so it is necessary to properly adjust the tension of paying off and adjust the eccentricity. It is generally used to produce wires and cables with small cross section, which are mostly used for insulation extrusion.

2. Semi extruded pipe extrusion.

The internal mold of the semi extrusion die has a tubular bearing diameter part, and the bearing diameter part is shorter. The end face of the internal mold is roughly located at 1/2 of the gallery section when it is pushed out. The extrusion mode is between the extrusion type and the extrusion type, and the sheath is closely combined with the core wire. The amount of glue released is relatively large. Its disadvantages are: If the flexibility of the core wire is poor, it is easy to produce eccentricity when it is bent in various forms; Moreover, when the cable core is not round and passes through the internal mold, it will swing and cause core deflection. It is mostly used for external extrusion, and vacuum extrusion can be used.

3. Squeeze tube eye mold.

The internal mold of the extrusion tube eye mold has a tubular bearing diameter part, and its bearing diameter part is longer. When being pushed out, the end face of the mold is flush with or slightly exceeds the external end face of the external mold gallery. The molten material is wrapped on the core wire through dropping, and the binding force between the sheath and the core wire is very small. The amount of glue is the most when it is pushed out. Its disadvantages are: The density of extruded sheath is poor; The vacuum extrusion can increase the tightness between the sheath and the core wire, and reduce the foaming phenomenon caused by the expansion between the core wires.