Generally, after water ingress into the cable, water tree aging will occur under the action of electric field, which may lead to cable breakdown. Water tree refers to the collection of voids filled with water with a diameter of 0.1m to several microns. Impurities, pores and uneven junction between insulation and inner and outer semiconducting layers in the insulation may become the incubation place of water tree. The development process of water tree is very long, generally more than 8 years. The higher the humidity, temperature and voltage, the more ions in the water, and the faster the development of water tree. During the storage period, the two ends of the newly purchased tubular cable will be sealed with plastic glands, but after a period of time, the rest of the cable will be wrapped with plastic paper and then wrapped with rope, which is not very good. Over the years, water vapor will naturally seep into the cable. During cable laying, the cable head wrapped with plastic paper may be immersed in water, which will also allow water to enter the cable. During traction and pipe threading, the outer sheath may be broken.

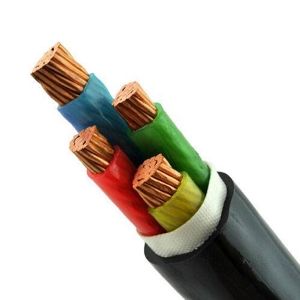

power cable The reason for out of tolerance of wire products: the wire core or cable core is not round and there is snaking, which will make the outer diameter change greatly, and the semi-finished products will certainly have quality problems. Common problems include poor steel belt joint, loose steel belt wrapping, steel belt curling, loose cable wrapping, improper cable pitch, and protruding or "riding" steel wire. The size of the mold core is too large or the mold core opening is damaged, which will cause the glue pouring, leading to the eccentricity of the plastic layer. When adjusting the mold, the mold adjusting screw is not tightened, which will also lead to the undercut phenomenon, leading to the eccentricity of the plastic layer, and the ammeter or voltmeter is constantly swinging left and right, This situation directly leads to the out of tolerance of cable plastic layer size caused by unstable screw and traction. In the process of plastic extrusion, too high temperature rise or blockage at the feeding port and filter screen may lead to less glue discharge and cable out of tolerance.

What are the causes of cable burning? Excessive temperature control will cause plastic burning; The screw has been used for a long time but has not been cleaned even though it is not cleaned; The time for heating and paying the bill is too long, and the plastic deposit is heated for a long time; The shutdown takes too long to clean the head and screw; Multiple mold or material changes during production; The head gland is not pressed tightly; The temperature control instrument fails. These are the causes of cable burning after ultra-high temperature.

Most cable manufacturers use universal copper rods, but because copper itself is not oxygen free, the surface of copper will inevitably contact with the air during processing and then oxidize. This also led to the trend of introducing advanced production technology of oxygen free copper in large quantities and developing oxygen free copper production technology by ourselves. This undoubtedly greatly improves the blackening problem of the cable coil. However, due to the immature use of the toughening process of copper rods by workers and the poor storage conditions of the finished copper wire cores, the copper wires will be slightly oxidized.

Cables shall not be placed in places containing acid, alkali and high corrosivity (except under special circumstances). During cable installation, the connection phase color of the cable cannot be linked incorrectly. East China cable. The connecting bolt at the cable connection should be firmly connected. When connecting the cable, the link marks at both ends should be completely consistent; When connecting the cable, pay attention to check the insulation between the cable and the motor, but do not test the insulation after connecting the cable to the inverter module. It is forbidden to use the cable with mechanical damage, and it is not allowed to walk on the cable. When connecting cables and plug-ins, attention must be paid to waterproof, and it is forbidden to clean any electrical equipment with water. When the cable is disassembled, it is not allowed to drag the cable vigorously, which may easily lead to cable damage and external links falling off. Cable installation under different conditions should be completed according to the corresponding regulations and operating procedures, including later maintenance and management