PV cable Difference from ordinary cables

Table 1

performance Ordinary cable PV cable

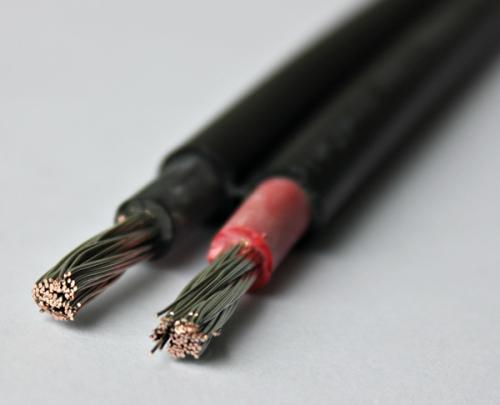

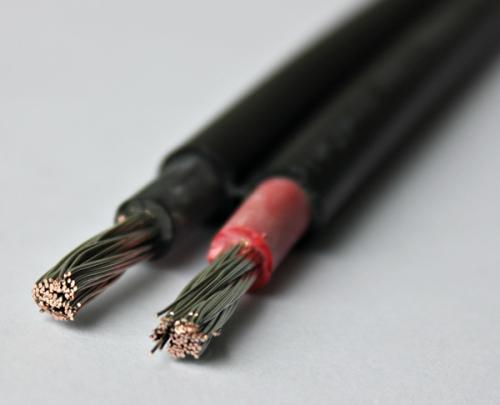

conductor Copper conductor or tinned copper conductor Copper conductor or tinned copper conductor

insulation PVC or XLPE insulation Irradiation cross-linked polyolefin insulation

sheath PVC sheath Irradiation cross-linked polyolefin insulation

Analysis (1) For ordinary cables, it can be seen from Table 1 that the conductors used are consistent with photovoltaic cables.

(2) It can be seen from Table 1 that the insulation and sheath of ordinary cables are different from photovoltaic cables.

(3) Ordinary cables are only suitable for laying in ordinary environment.

(4) PV power cable Advantages: high temperature resistance, cold resistance, oil resistance, acid and alkali resistance, UV protection, flame retardancy, environmental protection. Photovoltaic power cables are mainly used for gases in harsh environments

Later, the service life is more than 25 years.

Photovoltaic cables are often exposed to the sun, and the solar system is often used under the premise of poor environment, such as low temperature and ultraviolet radiation. At home or abroad, good weather will cause

The maximum on-site temperature of the solar energy system is up to 100 ℃, Various materials generally adopted for ordinary cables include polyvinyl chloride (PVC), rubber, elastomer (TPE) and cross-linked polyethylene

(XLPE) and other high-quality interlaced link materials, but unfortunately, the maximum rated temperature of ordinary cables is 90, and even the rated temperature is 70 ℃ PVC insulated cable Also

It is often used outdoors, but cannot meet the requirements of high temperature, ultraviolet protection and cold resistance. Now the national "Golden Sun Project" is being promoted nationwide, and many contractors do not choose

The photovoltaic cable supporting the solar system is replaced by ordinary "PVC" cable, which obviously will greatly affect the service life of the system.

Resistance to machine loads. For photovoltaic cables, during placement and application, the cables can be routed on the sharp edges of the roof layout, and at the same time, the cables must withstand pressure, bending, tension, interlaced tensile load and resistance

The force striking performance is superior to that of ordinary cables. If ordinary cables are used, the UV protection performance of the sheath is poor, which leads to the aging of the cable's outer protection, thus affecting the service life of the cable, which can lead to short cable

The presentation of road, fire alarm and staff dangerous injury problems. After irradiation, the insulation sheath of photovoltaic cable has high temperature resistance, ultraviolet radiation resistance, oil resistance, cold resistance and other properties, with a service life of 25

More than years old, this is unmatched by ordinary cables.